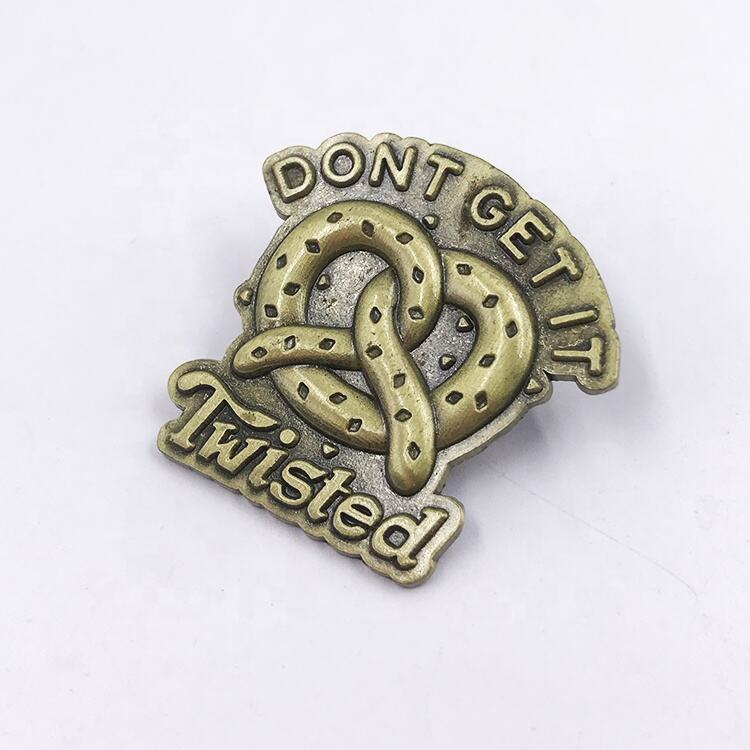

hard enamel custom pin

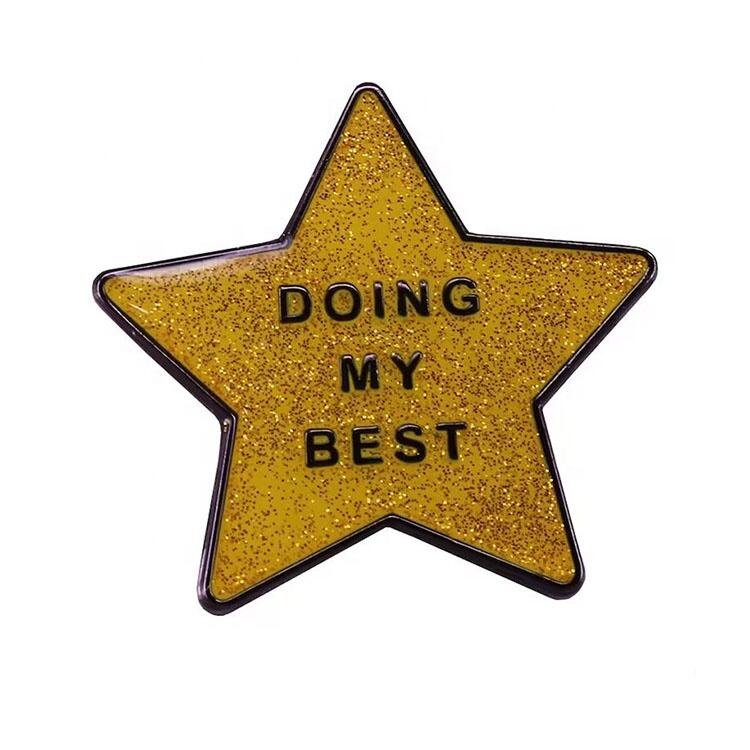

Hard enamel custom pins represent a premium quality crafting method in the pin-making industry, combining durability with artistic excellence. These pins are created through a sophisticated process where metal recesses are filled with colored enamel and polished to achieve a smooth, glass-like surface. The manufacturing begins with die-striking high-quality metal to create raised borders that separate different color areas. Each color is carefully applied and baked at high temperatures, resulting in a robust finish that resists scratches and maintains its vibrancy over time. The final product undergoes meticulous polishing to ensure the enamel and metal surfaces are perfectly level, creating a seamless appearance. These pins typically feature intricate designs with clean lines and sharp color separation, making them ideal for corporate branding, commemorative events, or collector's items. The plating options include gold, silver, copper, or black nickel, offering versatility in aesthetic appeal. Modern manufacturing techniques allow for detailed customization, including size variations from 0.75 to 2 inches, multiple color combinations, and various backing options such as butterfly clutches or magnetic closures.