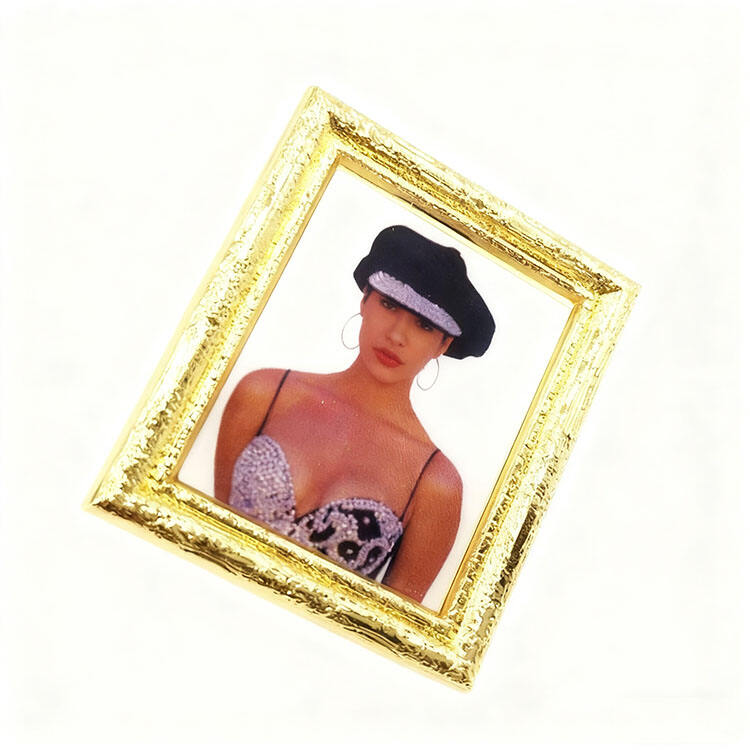

custom 3d printed badge

Custom 3D printed badges represent a revolutionary advancement in personalized identification and branding solutions. These badges combine cutting-edge additive manufacturing technology with customizable design elements to create unique, professional-grade identification pieces. The manufacturing process utilizes high-quality materials such as PLA, ABS, or resin, allowing for intricate details and durability. Each badge can be precisely engineered to feature specific dimensions, shapes, colors, and text layouts, making them ideal for corporate events, conferences, or organizational identification needs. The badges can incorporate various design elements including raised lettering, embedded logos, textured surfaces, and even complex geometric patterns that would be difficult to achieve with traditional manufacturing methods. The production process involves digital design creation, followed by layer-by-layer construction using advanced 3D printing technology, ensuring consistency and accuracy in every piece. These badges can also feature mounting options such as pin backs, magnetic attachments, or lanyard holes, providing versatility in wearing methods. The customization options extend to size variations, thickness adjustments, and multiple color combinations, allowing for perfect alignment with brand guidelines or event themes.