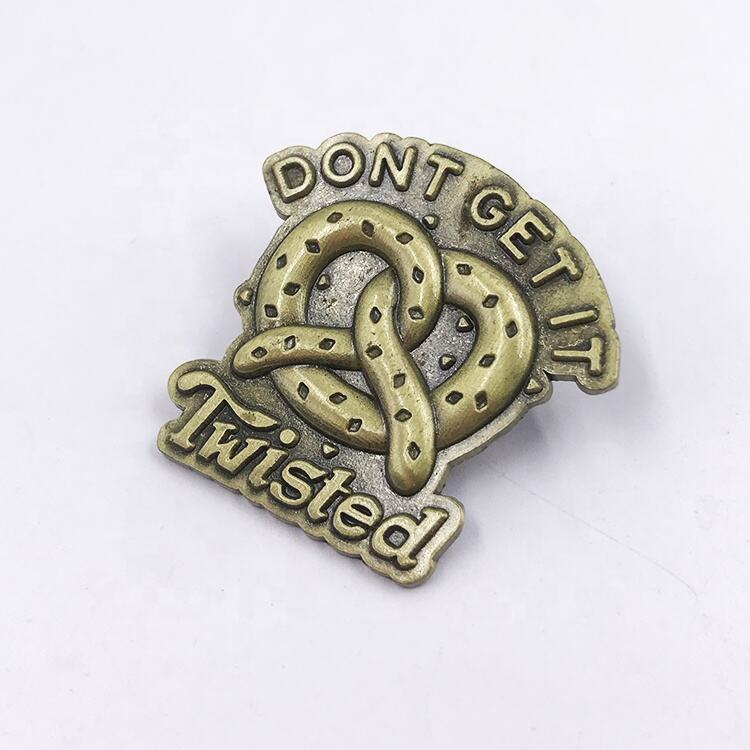

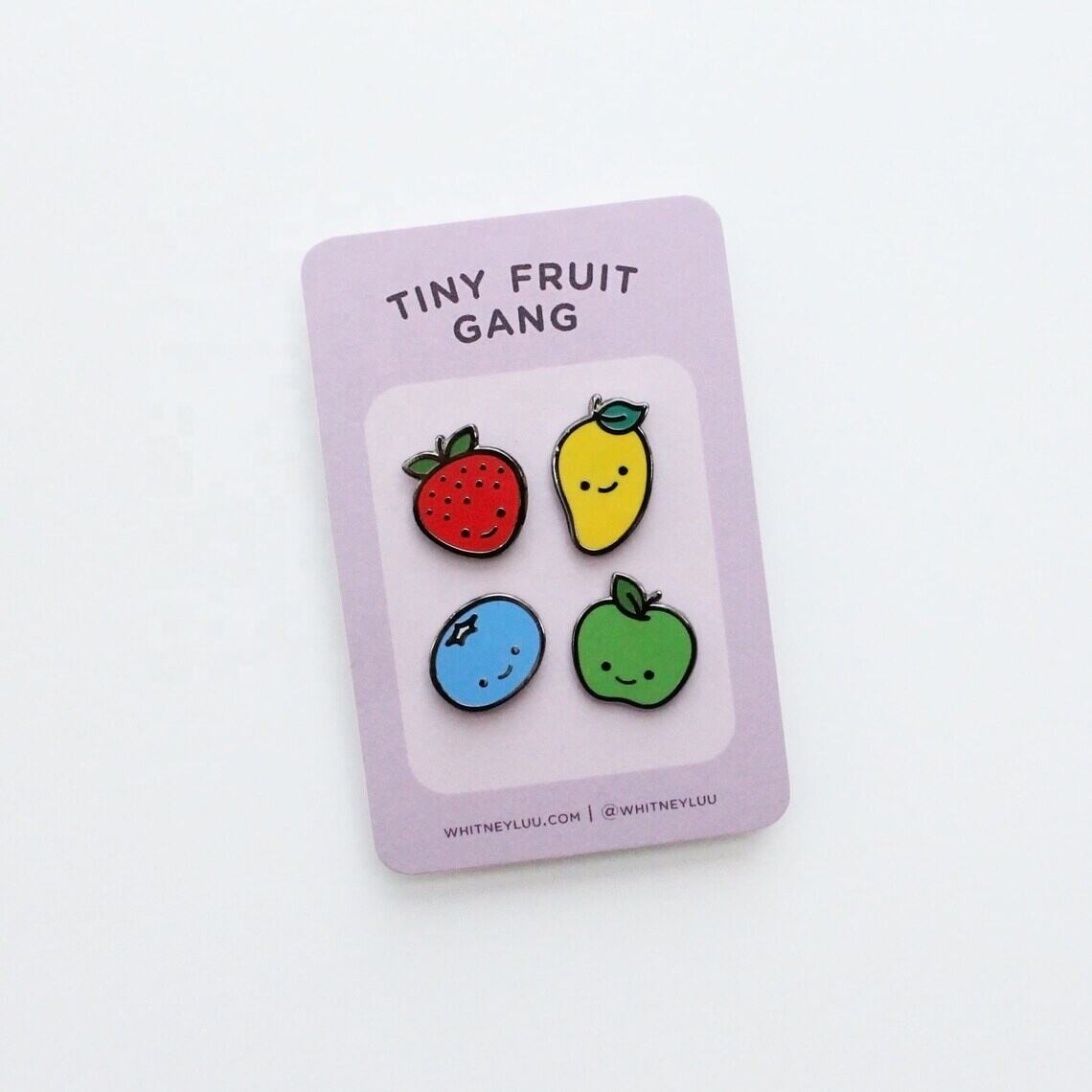

custom shaped enamel pins

Custom shaped enamel pins represent a unique blend of artistry and personalization in accessories. These meticulously crafted pins are manufactured through a sophisticated process that begins with die-striking metal bases into specific shapes, followed by carefully filling recessed areas with colored enamel. The pins can be produced using either soft or hard enamel techniques, each offering distinct aesthetic qualities. Soft enamel creates a textured effect with raised metal borders, while hard enamel provides a smooth, glass-like finish level with the metal edges. Advanced plating options including gold, silver, copper, or black nickel enhance their durability and visual appeal. These pins typically range from 0.75 to 2 inches in size and feature intricate designs that can incorporate multiple colors, textures, and finishing effects. The manufacturing process ensures color accuracy and detail preservation, making them ideal for brand representation, commemorative purposes, or personal expression. Various attachment options, including butterfly clutches, magnetic backs, or safety pins, provide versatile wearing possibilities. The pins undergo quality control measures to ensure color consistency, durability, and proper attachment mechanism functionality.